C Type presses

4 Columns type

Straight Side type

Die Spotting press

Hydroforming Presses

Recycling Plant for Polyaluminum

DO YOU NEED A SPECIAL PROJECT?

CONTACT

1.- HYDRAULIC PRESSES, THE OPTION IN PRESSES

TODAY, THE HYDRAULIC PRESSS IS THE PREFER SELECTION

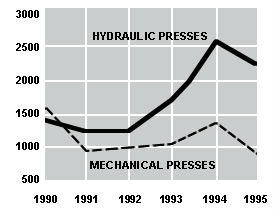

During the last 30 years, there has been a growth in the use of hydraulic presses. For many years the use of mechanical presses was favored; which uses the system of a crankshaft that rolls or rotates.

Since 1991 the shipments of hydraulic presses have surpassed the mechanical presses that are now preferred in the world manufacture.V

2.- HYDRAULIC PRESSES

* Faster and more reliable than ever.

Today they look even faster and more reliable than ever due to improved technology, including new seals, better pumps, reinforced hoses and improved couplings.

Also the use of PLC controls (Programmable Logic Control) and other electronic controls has improved the speed and flexibility of these presses in the manufacturing process, with the integration of the presses with Interfaces with the computation and monitoring of processes.

* More productive in manual feeds.

Mechanical presses are often fast in automatic feeds, short strokes and short feeds for punching operations.

Then, manual feeding and hydraulic presses offer obvious competitive advantages in manual feeds.

ADJUSTMENTS AND QUICK CHANGES OF TOOLS

Another advantage of hydraulic presses is that they are very easy to change the tooling and then continue with a new job. It is especially important when it comes to adjusting the stroke of a mechanical press, because the hydraulic press can maintain maximum force throughout the entire race, so you do not have to worry about the maximum force point.

Also, as it gives you the same time to make the changes to other jobs, be it a bench or a pedestal (floor), when the work is done by hand, the saving of assembly time or changes makes them to the hydraulic presses even more useful than the mechanics.

Although there has been a tendency to use the automation process with mechanical machines with automatic feeding, there are mostly manufacturing processes on the contrary, they require manual feeding due to the characteristics of the material or the high cost of the automation processes. Also the need for quick deliveries or smaller orders for the products, it is urgent to manufacture in short periods instead of investing a lot of capital in automation power equipment. In these situations hydraulic presses are best for minimum cost, their flexibility and not having to spend much time in the settings of the automation equipment.

FLEXIBILITY IN MANY APPLICATIONS.

Nowadays hydraulic presses are seen in high volume works in manufacturing processes such as the following:

- The assembly of the arrows to the motor shafts, sheet compression or the center of the inserts.

- The formation of any metal in pieces such as cutlery or metal pots.

- In the automotive industry, insert the axles to the water pumps, the bearings to the transmissions, the assembly of the shock absorbers, blanks, formation of diaphragms or the disc brake joint.

- In the aeronautical industry.

3.- 10 ADVANTAGES OF THE USE OF HYDRAULIC PRESSES

1 - TOTAL FORCE IN ALL STROKE

- Es posible mantener el total de la fuerza a lo largo de la carrera, no solamente al final de la carrera como en las prensas mecánicas. La ventaja de esto es quitar la necesidad de hacer cálculos de la presión del tonelaje al principio de la carrera, así es que no se requiere la compra de una prensa de 200 toneladas para alcanzar a la presión de solamente 100 toneladas.

2 - MORE CAPACITY, LOW COST

- Se sabe que es más fácil y menos caro comprar ciertas clases de capacidad en las prensas hidráulicas. Las carreras de 12, l8 y de 24 pulgadas son comunes. Aparte, es fácil aumentar esta medida. También se puede aumentar el claro máximo a bajos costos. Inclusive, es muy posible la instalación de las mesas (platinas) más grandes en las prensas pequeñas o el aumento de cualquiera platina.

3 - LOWER PURCHASE COST

- Por su potencia de fuerza no hay ninguna máquina que dé la misma fuerza por el mismo precio.

4 - LOWER MAINTENANCE COST

- Las prensas hidráulicas son bastantes sencillas en su diseño, con pocas partes en movimiento y están siempre lubricadas con un fluido de aceite bajo presión. En las pocas ocasiones de avería casi siempre son defectos menores, ya sea el empaque, la bobina solenoide y a veces una válvula, que son fáciles de refaccionar. En cambio, en las prensas mecánicas, un cigüeñal roto es significativo, tanto en el costo de la parte como la pérdida de producción. No sólo es el menor costo de estas partes, sino también se puede reparar sin tener que hacer maniobras de desmontar piezas de gran tamaño; reduciendo tiempos de mantenimiento y menos afectación en la producción.

5 - SECURITY OF OVERLOAD INCLUDED

- Con una prensa de 100 toneladas si se calibra una fuerza de 100 toneladas, no se corre el riesgo de romper troqueles o la misma prensa por un excedente de fuerza; por que al llegar al máximo de fuerza permitida, se abre una válvula de seguridad.

6 - GREATER FLEXIBILITY IN CONTROL AND VERSATILITY

- Como siempre se puede mantener el control en una prensa hidráulica de la fuerza, carrera, tiempo de trabajo, movimientos con secuencia, etc. Se puede disponer de una velocidad rápida de aproximación y otra de trabajo, con ventajas de productividad y de cuidado de herramental. En una prensa hidráulica se pueden controlar distancias de profundidad, aproximación, tiempos de trabajo o toda una secuencia de operación, por medio de temporizadores, alimentadores, calentadores, etc. Por este motivo una presas hidráulica no solo sube y baja, como lo haría una prensa mecánica.

Una prensa hidráulica puede hacer trabajos en un amplio rango según su fuerza. Entre ellos son: embutido profundo, reducción, formado de polímeros, formado, estampado, troquelado, punzonado, prensado, ensamble ajustado, enderezado. También es muy útil en los procesos de formado de sinterizado de ruedas abrasivas, adhesión, brochado, calibración de diámetros, compresión del plástico y hule (goma, caucho) y troqueles de transferencia.

7 - MORE COMPACT

- Aunque una prensa de 20 toneladas mide 1.7 mts. x 0.7 mts. x 1.5 mts., una prensa de 200 toneladas sólo mide 2.1 mts. x 1.2 mts. x 2 mts., con efectivamente 10 veces la capacidad pero solo un poco más grande; la prensa más grande desplaza solo 50% más. Como va incrementando la fuerza, se va economizando comparando a las prensas mecánicas.

8 - LESS EXPENSES ON TOOLS

- Se pueden fabricar las herramientas según las tolerancias de un trabajo en específico, después ajustar la fuerza de la prensa hidráulica según ésta misma. El hecho de que hay un mínimo choque y vibración, redunda en un beneficio de más vida en los herramentales.

9 - LESS NOISE

- Con menos partes movibles y sin rueda volante, el nivel de ruido iniciado por la prensa hidráulica es mucho menor que la mecánica. Armadas según normas, aunque estén trabajando a toda presión, las bombas emiten un menor ruido que el indicado en las Normas Federales. También es posible minimizar el nivel de ruido al controlar la velocidad del vástago al pasar por el trabajo más lento y suave.

10 - SECURITY

- No queremos decir que las prensas hidráulicas sean más seguras que las mecánicas. Las dos clases son seguras si se instalan y se usan de manera apropiada, pero con los controles a dos manos y los protectores enlazados, es más fácil proporcionar más seguridad por el hecho de tener un control completo del sistema hidráulico.

4.- VOCABULARY

1- CYLINDER - It is the total assembly of a cylinder or piston made up of the shirt, the piston rod, the gaskets and the seals. The diameter of the piston and the pressure of the oil (fluid) are the elements that determine the force (tonnage) given by a press.

2- STRUCTURE - It is the main body of the press that consists of the cylinders and the surface where the work is done.

3- RACE CONTROL - The length of the stroke can be calibrated and controlled of any size between the limits of the cylinder. The settings are: to the top of the race, to the point of pre - calibration or to the end (background) of the race.

4- CLEARING OF NECKLACE (C type presses) - It is the distance from the line of the center of the shank to the vertical structure behind the base of the stage. In this distance the maximum diameter of the largest piece that can be placed to work with the center of the piece (raw material) placed (aligned) with the center of the stem comes out.

5- MAXIMUM DAYLIGHT - It is the vertical distance from the top of the stage to the lower surface of the shank in its highest position. It is sometimes confused with the term "clear closed". The closed clear is the clear on the base of the plate with the stem at full depth. The "maximum clearing" means the maximum vertical capacity of the press.

6- THE PLATE - It is a plate or structure armed on the base of the plate that in most models is a removable plate.

7- PLATE BASE - It is a flat turned surface that holds the plate or the dies.

8- TWO-HAND CONTROLS - It is the most common way to start the cycles of hydraulic presses. It is required to press the 2 buttons of the controls at the same time to lower the shank, so it is necessary for the operator to use both hands to operate the machine. Based on the safety standards, the controls have the following conditions: 1.- no-repetition: Even if the operator keeps the cycle buttons activated, the machine does not start a new cycle; 2.- Activation by time: the operator must activate the two buttons in a time lapse between 0.2 and 0.4 seconds, that is, if the two buttons are not kept for at least 0.4 seconds and when activated the time difference between one and another is greater than 0.2 seconds, the press will not start the cycle.

9- WORK HEIGHT - It is the distance from the floor to the top of the stage where the work is done.

ANOTHER VOCABULARY ABOUT THE HYDRAULIC:

THE GRINDER OF THE RAW MATERIAL - It is a controlled force to retain the edges of the raw material during the operations of deep stuffing. It is similar to the cushion cushion.

HYDRAULIC CUSHION - It is a hydraulic or air cylinder placed under the platen and under the base of the platen that provides a uniformity in the retention of the piece in the operations of deep stuffing. The cushions also pull out the pieces made outside the punching machine or the dies. They can be installed alone or with a mobile stage.

REVERSE DISTANCE CONTROL - It is an adjustable limit switch control to calibrate the depth of the stroke before returning (climbing, returning).

ADJUSTABLE TIMER IN CARRERA - It is a timer to calibrate the stay time of the piston rod when it reaches its stroke depth under pressure. It is also used to maintain the time of a series of press operations.

HEAT EXCHANGER - It is a device next to the oil tank to circulate water or air in order to maintain the temperature of the oil at an adequate level of operation.

EXTRACTOR - It is a device that is used to remove the piece from the punch or die.

PLATE - It is a plate usually hot, armed to a movable part of the press.

REVERSE PRESSURE CONTROL - It is an adjustable control to calibrate and maintain the force at which the press shank is counter-locked.

5.- DATA AND USEFUL FORMS

HOW TO CALCULATE THE REQUIREMENTS (NEEDS) OF TONNAGE:

1- IN GENERAL: When the force per square inch is known: PSI x work area / 2000 = tonnage of force required.

EXAMPLE: When it is known that 100 psi is required to do a job work on a product (raw material) of 5" x 8". 100 x (5"x8")/2000=2 tons.

2- ASSEMBLE JUST: To determine the force required to join two round pieces such as a tight shaft inside a bushing, use the following formula:

F=D x π x L x I x P/2

Where:

F= required force in tons.

D= diameter of the piece which will be press, in inches.

L= "blank" length (the piece) that is pressed, in inches (Note: it should be only the length of the interference fit).

I= the interference in inches (usually between 0.002 to 0.006).

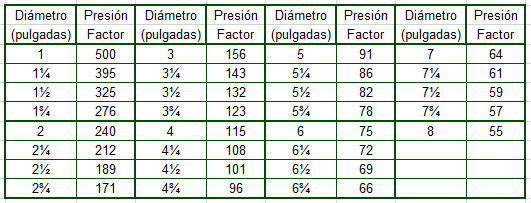

P = Pressure Factors (force) (See the table below)

FORCE FACTORS*

EXAMPLE: An arrow (shaft) with a diameter of 2". Pressed into a bearing or hole 3" long.The interference fit between the two diameters results in 0.006 ".

F= (2” x 3.14 x 3” x 0.006) x (240÷ 2)

F= 13.56 tons.

3- PUNCHING - A rapid guide to calculate the needs of tonnage to punching the steel is:

Diameter x thickness x 80 = tons of force (where 80 is a constant (fixed) with the steel. Use 65 for bronze).

EXAMPLE: For a hole of 3" with material of 0.250“ thickness.

F= 3" x 0.250" x 80

F= 60 Tons.

For no-circular holes, instead “diameter”, is used 1/3 of total from the length of cut. (the cut).

EXAMPLE: For a rectangular hole of 4" x 6" and 0.250" thickness.

F= (4" + 6" + 4" + 6" / 3) x 0.250 x 80

F= 133.3 tons.

4- DEEP DRAWING - The calculations or the calibration of Deep Drawing can be complex. The press, the dies, the material, even the radio and the piece count in the completion of the process.

For round helmets the following formula serves as a guide:

C x T x Ts = tons.

Where:

C= the circumference of the finished piece.

T= the thickness of material, in inches.

Ts= the tension force of material, in PSI.

EXAMPLE: To draw a 5" diameter cup in 0.040" thick material with a tensile stress of 46,000 psi.

F= (5 x 3.1416) x .040 x (46000/2000)

F= 14.44 tons.

A 20 tons. press is recommended.

Notes:

1- These formulas intend to serve as guides only. You need to consult with an engineer to verify the specific requirements of each process.

* 2- It has a steel bar and a iron bushing (with OD/ID ≥ 2).

5- STRAIGHTENED - The force required to straighten the metal piece depends on its shape. Below is the formula with more explanations for the different forms:

Where:

F= the strength of the shank in tons.

6= a constant.

U= represent "Last maximum force” of the material in PSI.

Z= section “modulus” (see below).

L= represent the distance between straightening blocks per inch.

Solid and round material.

Solid and square material.

Hollow and rectangular material.

EXAMPLE: On a bar (or axle) of 2" in diameter, with 18" between the blocks, with 100,000 psi maximum force.

HOW TO CALCULATE HOW MANY CYCLES PER MINUTE NEED A HYDRAULIC PRESS

The number of stroke per minute for a hydraulic press is determined by calculating the particular time of each phase of the stem stroke. The fast approach time is calculated; the force time (work stroke); then, if there is no depth duration, the fast return (return).

The basic formula to determine the duration on seconds of each phase of the stroke is:

Where:

T= Time in seconds.

D= Distance of a phase of the rod in inches.

IPM= Rod speed in inches per minute (ipm).

EXAMPLE: A hydraulic press with 600 ipm of fast advance, with 60 ipm of speed of force, and with 600 ipm of fast return.

The work requires an advance of 3", 1" stroke and 4" fast return.

Valve displacement: 0.500*

* Time it takes to act the valve, it is normally calculated half second.

Total time: 2.199 seg.

6.- GUIDES TO SELECT A HYDRAULIC PRESS

1.- THE TONNAGE (Force) - Is the same force required from a hydraulic press or a mechanical press to do a work? It is said that yes. Distinctions are not highlighted in force calculations or tooling that is interchangeable. There are certain applications of deep drawing in which the force stroke of a hydraulic press decreases, but it is not known of cases in which this demands the use of a press of more force (Tonnage).

Sometimes, the selection of a press can be a riddle.

For example, if a job is done at 150 tons in a mechanical press, it may be that the work is actually done with 100 or 75 tons, but they have not really been tested with those tonnages.

On the other hand, with the hydraulic press it is easy to adjust the adequate and precise force for each type of work in particular.

2.- THE MACHINE ACTION - Is the same effect of the stroke in a hydraulic press as in a mechanical press? The answer is yes, in most cases, but there are exceptions. Hammer presses and some mechanical presses are better for jewelry production and impact work. On the contrary, in deep-drawing jobs, a hydraulic press makes them better.

Apart from those cases, there are few examples where the results with a hydraulic press produces a significant effect that with the mechanical presses working the same tooling.

The shear (shear) is the same in the two types of machines.

3.- SELECTION OF THE PRESS TYPE - "C" tYPE presses offer the advantage of access from three sides. The presses "Four Columns" type ensure a very parallel force. The presses of "Straight Sides" type gives us the rigidity sufficient to do the works of transfer.

The more critical the work is and the more tolerance is demanded, is bigger the range reserve in tonnage that it should have.

4.- ACCESSORIES - Nowadays, most manufacturers offer a wide range of accessories that include the following:

- Control of movements by electromechanical limits.

- Return by tonnage (pressure).

- Automatic continuous cycle control.

- Adjustable stroke timer.

- Movable plates and with rotating head.

- Hydraulic or pneumatic cushion.

- Ejector cylinders.

- Electronic light curtains or other systems.

- Control with touch screen.

- Proportional hydraulic systems, for precise, constant and repetitive control.

5.- QUALITY - It is known that there are several classes of the quality of machines. There are lighter presses capable of giving the material a "light touch" and then returning; there are also heavy contraction presses to work the metal well.

These are some of the details on the construction of the presses that must be considered in order to make a good comparison between the presses.

> THE FRAME.- Look at the construction of the structure: its rigidity, the thickness of the plate, its capacity for dimensions and other factors.

> THE CYLINDER.- What is its diameter? How is it built? What company manufactured it? Is it easy to give service?

> THE MAXIMUM PRESSURE OF THE SYSTEM.- What pressure is wanted in the system so that the press reaches its maximum force? Usually it should be between 1,000 and up to 3,000 PSI.

> ELECTRIC MOTOR.- They are the duration, the length of the stroke and the speed of the "stroke of force" that determine the amount of Force in Horses that is needed for a work. Look at the indicated powers.

> SPEED.- See point 5 to determine the speed of a hydraulic press.

7.- LIMITATIONS OF THE HYDRAULIC PRESSEST

SPEED.- There is no hydraulic press that is as fast as a mechanical press. If it only matters that the press is fast and the feed is short, a mechanical press is better.

STROKE LENGTH.- With the use of a limit switch with electromechanical limits, only a tolerance of 0.020" is expected, with the electronic stroke control (linear scale) a tolerance of 0.010" can be expected.

Many presses can be adjusted to go back as soon as a pre-selected tonnage is reached, thus, the pieces are uniform.

If even more precision is required, the mechanical stops can be used in the tooling.

Nowadays, the "Servo-hydraulic system" is a very precise system and thus the control over tolerance is minimized, with the guarantee of more constant and equal results. This usually eliminates the need for mechanical stops.

AUTOMATIC FEEDER EQUIPMENT.- Hydraulic presses require another external force to feed the raw material. The feeder requires its own force, then it has to be integrated with the press control system. However, nowadays there are new feeding systems: rolls, hooks or air.

HIT AFTER INITIAL TIME IN PUNCHING PROCESS.- Both presses, hydraulic and mechanical, suffer from this problem, but the hydraulic system also requires a blow isolator related to decompression. Without this protection, such hit can damage lines and connections.

NOTICE: These reports only serve as guides or suggestions and should be cleared by an engineer. They should not be taken as a guarantee or liability for contract

Quality of our presses is based on manufacturing according to International Standards:

Precision Metalforming Association

ASSOCIATE MEMBER

Hydraulic Presses:

ANSI B11.2., JIS.

Hydraulic Units:

ANSI-NFPA-T3.163 R1-97.

Hydraulic

Systems:

JIC-H-73.

Electrical Standard for Machinery: ANSI/79-1994.

Welding in Hydraulic Frame Presses:

AWS-D14.5-97.

NOTICE OF PRIVACY

© Fluidica S.A All rights reserved

Web Design: GLIFO MEDIA